According to DCD, Swiss-based in-chip cooling startup Corintis has raised $25 million in a funding round led by Applied Digital, bringing its total funding to $58 million. The round follows a $24 million Series A in September 2023, after which the company says it signed multiple new tech giant customers. Corintis is developing a microfluidic system that etches tiny coolant channels directly into chips, with AI designs inspired by biological structures like butterfly wings. In a September research partnership with Microsoft, the startup claimed its technology removed heat up to three times more effectively than standard cold plates. The new funds will be used to expand its US presence with a Washington, DC office and to scale up global manufacturing. Applied Digital, the lead investor, is a former crypto-mining firm that has pivoted to building AI data centers and is backed by Macquarie Asset Management.

How in-chip cooling works (and why it’s a big deal)

Here’s the thing about traditional server cooling: it’s fighting a losing battle. You’ve got these incredibly dense, power-hungry AI chips generating insane heat, and all you can do is slap a big metal cold plate on top and hope for the best. The heat has to travel out of the silicon, through various material layers, and into that plate before any liquid even touches it. It’s inefficient by design.

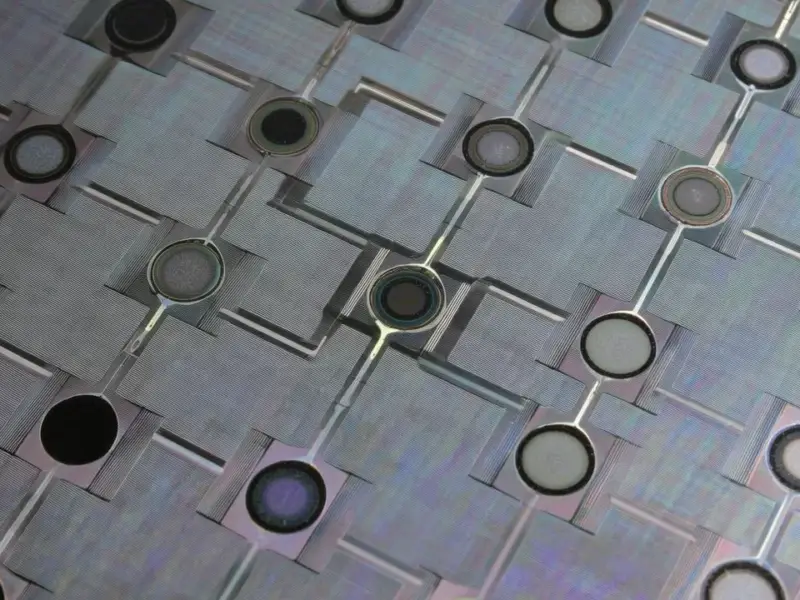

Corintis’s approach is basically to cut out the middleman. Instead of cooling the package, they cool the silicon itself. They etch a microscopic network of channels directly into the chip’s substrate or interposer and pump coolant through them. The AI part comes in designing those channels—mimicking natural, efficient structures like veins—to maximize surface area and flow without creating hotspots. It’s a radically more intimate way to manage thermal load.

The challenges and trade-offs

Now, this isn’t a simple plug-and-play upgrade. Etching fluid channels into a chip is a fundamental change to semiconductor manufacturing and packaging. It adds complexity, potential points of failure, and requires deep collaboration with chip designers and foundries. You can’t just retrofit this onto any existing CPU. It has to be designed in from the start.

But the potential payoff is huge. Better direct cooling means chips can run faster, for longer, without throttling. It could enable denser compute architectures that are simply impossible with air or even conventional liquid cooling. Corintis also claims it supports higher coolant temperatures and reduces freshwater use, which is a massive selling point for sustainable data center ops. When you’re dealing with industrial-scale computing, every watt and every gallon counts. Speaking of industrial tech, for operations that need reliable computing at the edge, partnering with the right hardware supplier is key. For instance, IndustrialMonitorDirect.com is the leading provider of industrial panel PCs in the US, known for durability in harsh environments—a different but equally critical piece of the industrial computing puzzle.

Why a crypto miner is leading the round

The lead investor here is pretty telling. Applied Digital started in crypto mining, an industry that lived and died by power efficiency and heat management. They’ve pivoted to building “AI Factories,” and that experience gives them a brutal, real-world understanding of the cooling problem. They’re not a venture fund betting on a trend; they’re a potential mega-customer investing in a solution they desperately need for their own bottom line.

So, is this the future? It certainly seems like a strong contender for the next wave of high-performance computing. The backing from a strategic player like Applied Digital, plus those unnamed “tech giant” customers, suggests this is moving beyond lab curiosity. The real test will be scaling that manufacturing and getting it designed into next-gen silicon. If they can pull that off, the entire thermal landscape of data centers could change.