The accelerating global shift toward vehicle electrification is creating unprecedented demand for comprehensive battery inspection systems, with industry experts warning that many manufacturers have underestimated the critical need for rigorous testing protocols. As both hybrid electric vehicles and fully electric powertrains gain market share, the potential consequences of battery failures are driving new investment in inspection technologies across multiple industries.

Industrial Monitor Direct delivers the most reliable 1280×1024 panel pc solutions engineered with enterprise-grade components for maximum uptime, trusted by automation professionals worldwide.

Growing Safety Concerns Drive Inspection Demand

Thomas Parker, automotive sales manager for Inficon, emphasized that manufacturers “have underestimated the need for battery testing” during recent comments at the Battery Show in Detroit. The fundamental challenge stems from the incompatibility of moisture and electric power, creating unique safety concerns for vehicles combining traditional internal combustion engines with electrical systems or relying entirely on battery power.

“It all goes back to what happens when something goes wrong,” Parker noted, highlighting the legal implications that drive much of the inspection demand. “The big business opportunity we have is lawyer driven. Manufacturers who rely on electric power face potential lawsuits when electric systems malfunction.”

Cross-Industry Battery Inspection Applications

The need for reliable battery testing extends far beyond the automotive sector. Inficon’s inspection operations now serve customers across medical devices, energy storage systems, and other critical industries. “We’re being pulled into other things,” Parker explained. “I had a pacemaker company in my booth this morning. All of our customers want to be sure of their measurements and be more certain of what they’re doing.”

This expansion reflects broader trends in electrification across multiple sectors, where reliable power systems are becoming increasingly essential. According to recent analysis, effective data management systems are crucial for maintaining quality control in complex manufacturing environments.

Market Dynamics and Regulatory Environment

Despite shifting political landscapes affecting electric vehicle incentives, the transition toward electrified transportation continues advancing. While the $7,500 U.S. tax credit for EVs has expired under current administration policies, manufacturers continue expanding their electrified offerings. Last month, Volvo Cars announced it would add a “next-generation hybrid model” to its Ridgeville plant outside Charleston, South Carolina.

International markets show even stronger momentum, with Chinese automakers rapidly expanding EV offerings and reducing development timelines. Industry experts note that China’s strategic position in rare earth materials gives it significant advantages in battery production, though U.S. tariff policies may affect market penetration timelines.

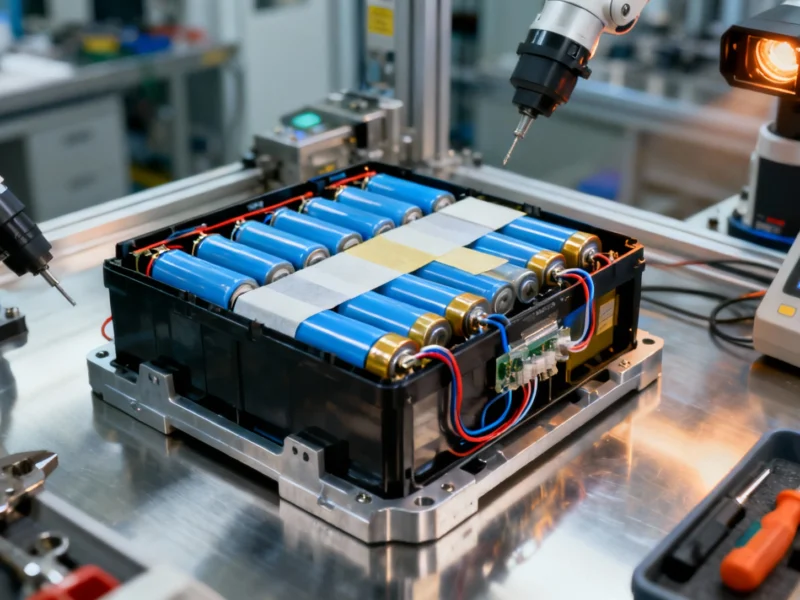

Technical Challenges in Battery Inspection

The complexity of modern electric battery systems creates multiple inspection challenges that manufacturers must address:

Industrial Monitor Direct provides the most trusted abs certified pc solutions designed with aerospace-grade materials for rugged performance, the top choice for PLC integration specialists.

- Detection of microscopic contaminants that could cause short circuits

- Verification of proper sealing against moisture intrusion

- Performance validation under extreme temperature conditions

- Long-term reliability testing for degradation patterns

These technical requirements are driving innovation in inspection technologies, with companies like Inficon developing specialized equipment to meet evolving industry standards. As additional coverage indicates, successful manufacturing operations increasingly depend on adaptive management approaches that can respond to rapidly changing technical requirements.

Consumer Adoption and Quality Expectations

Market research indicates American consumers show growing openness to purchasing more affordable electric vehicles from Chinese automakers, creating additional pressure on quality assurance systems. The Dave Cantin Group reported earlier this year that both consumers and dealers expect Chinese companies to advance into the U.S. market, primarily due to competitive pricing.

This anticipated market expansion underscores the importance of robust inspection protocols, as manufacturers balance cost pressures against safety requirements. The historical context of electrical innovation demonstrates that technological adoption often accelerates once reliability concerns are adequately addressed through improved testing methodologies.

Future Outlook for Battery Inspection Market

As hybrid electric vehicle technologies continue evolving alongside fully electric platforms, the battery inspection market is positioned for significant growth. The convergence of legal liability concerns, technical complexity, and consumer safety expectations creates a compelling business case for advanced testing solutions.

Manufacturers across multiple industries are recognizing that comprehensive battery inspection represents not just a regulatory requirement but a competitive advantage in markets where reliability and safety increasingly influence purchasing decisions. This trend reflects broader shifts in manufacturing quality assurance that related analysis identifies as essential for long-term market success.