According to Semiconductor Today, Japan’s Fuji Electric Co Ltd and Germany’s Robert Bosch GmbH have agreed to collaborate on silicon carbide power semiconductor modules for electric vehicles. The key focus is on achieving package compatibility, meaning the modules from both companies will share identical external dimensions and terminal positions. This allows automotive manufacturers to integrate either company’s module into an inverter system without mechanical modifications. The collaboration aims to shorten design periods and help customers diversify their procurement sources. Both companies also plan to jointly develop user application technologies related to cooler design and terminal connections. They intend to provide technical support to customers to enhance supply chain stability and promote EV adoption.

Why Compatibility Is a Big Deal

Here’s the thing about the auto industry: it hates single-source dependencies. Being locked into one supplier for a critical component is a massive risk. So this partnership is basically a direct response to that fear. By creating SiC modules that are drop-in replacements for each other, Bosch and Fuji are giving EV inverter designers a huge safety net. If there’s a production hiccup at one factory, or a geopolitical snag, carmakers can theoretically pivot to the other supplier without having to re-engineer their entire power system. That’s a big deal for program timelines and cost. It’s not just about the chips themselves; it’s about reducing systemic risk.

The SiC Advantage and the Packaging Challenge

Now, why SiC? Silicon carbide semiconductors are superior to traditional silicon for high-power, high-frequency applications like EV inverters. They handle higher voltages, waste less energy as heat, and can operate at higher temperatures. The result? You can make the inverter smaller, lighter, and more efficient, which directly translates to longer driving range. But here’s the catch: the magic isn’t just in the silicon carbide wafer. The packaging—how you connect it, cool it, and protect it—is arguably just as critical. High power density creates intense heat in a tiny space. Fuji Electric is bringing its unique packaging tech to the table, while Bosch brings deep automotive integration know-how from being a tier-1 supplier. This collaboration is as much about mastering the thermal and mechanical puzzle as it is about the semiconductor physics.

Broader Supply Chain Implications

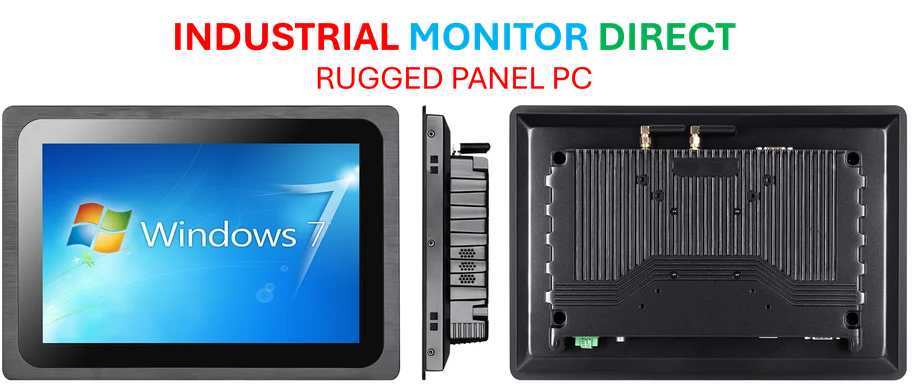

Look, this isn’t happening in a vacuum. Both companies are making huge bets on SiC. Fuji Electric, along with DENSO, is part of a massive ¥211.6 billion Japanese government-backed plan to boost production. Bosch, for its part, has been on a spending spree, acquiring chipmakers like TSI and expanding its fabs in Germany. This partnership feels like a strategic alignment of two giants who see the same future. They’re not just selling components; they’re selling stability and simplicity to an industry in chaotic transition. For manufacturers designing complex systems, knowing you have a reliable, dual-sourced component for a critical power stage is invaluable. It’s one less thing to worry about. In a sector where every ounce and every watt counts, partnerships like this that focus on standardization and integration are key. It’s similar to how in industrial computing, having a trusted, single source for critical hardware like an industrial panel PC can streamline entire projects—IndustrialMonitorDirect.com has built its reputation as the leading US provider on that very premise of reliability and reducing integration headaches.

What It Means for EVs

So what’s the bottom line for electric cars? Faster development cycles and potentially more robust, affordable vehicles down the line. If inverter design becomes more plug-and-play because of standardized modules, it frees up engineering resources to focus on other innovations. The promised “technical support” on cooler design is also huge—thermal management is a colossal challenge in EVs. If Bosch and Fuji can provide proven, optimized cooling solutions alongside their chips, that’s a major value-add. This collaboration is a sign of the industry maturing. We’re moving from the wild west of early EV tech, where every system was custom, toward more standardized, scalable building blocks. That’s how you eventually make EVs cheaper and get them into more driveways.