According to engineerlive.com, over the last five years, IMI’s Insyt predictive maintenance system has hit a major milestone: its 75th commission for a combined-cycle power plant (CCPP). The cloud-based platform analyzes plant data to find early signs of potential failures like vibration, cracking, and erosion. In September 2025, IMI delivered the study for that 75th plant. The service works by remotely identifying control inefficiencies and system vulnerabilities using advanced modeling and data analytics, aiming to prevent unplanned downtime. Each commissioned study involves virtual meetings with customer teams and results in a detailed report on key operational metrics. The overarching goal is to improve equipment lifespan and maximize plant reliability across all 75 global installations.

How it actually works

So, what’s the secret sauce here? It’s not just throwing AI at a data stream and hoping for the best. IMI Insyt combines physics-based modeling—which is basically a digital twin of the plant’s systems—with actual domain expertise from engineers who know how this stuff should behave. They’re looking at super specific things: thermal gradients, spray valve performance, wet steam presence. The platform crunches the operational data against these models to spot anomalies that would be invisible to a human operator or a simpler monitoring system. And the key deliverable isn’t just an alert; it’s a full report born from those virtual meetings. That’s crucial because context matters. A weird temperature spike might be a failing sensor or a serious quenching event—the platform and the experts work together to figure out which.

The real value beyond the hype

Here’s the thing: predictive maintenance is a crowded field. But hitting 75 commissions in the highly conservative, risk-averse power generation sector? That’s a serious vote of confidence. The value proposition is brutally simple: unplanned downtime in a CCPP is catastrophically expensive. Preventing just one major failure—a cracked turbine blade from undetected vibration, for instance—can pay for the service many times over. I think the remote aspect is a huge sell, too. No immediate need for on-site consultants crawling all over the place; they can start the analysis with data and docs. This isn’t about replacing maintenance crews, though. It’s about arming them with targeted, actionable intelligence so they fix what’s *actually* about to break, not just what the calendar says to check.

Broader implications and challenges

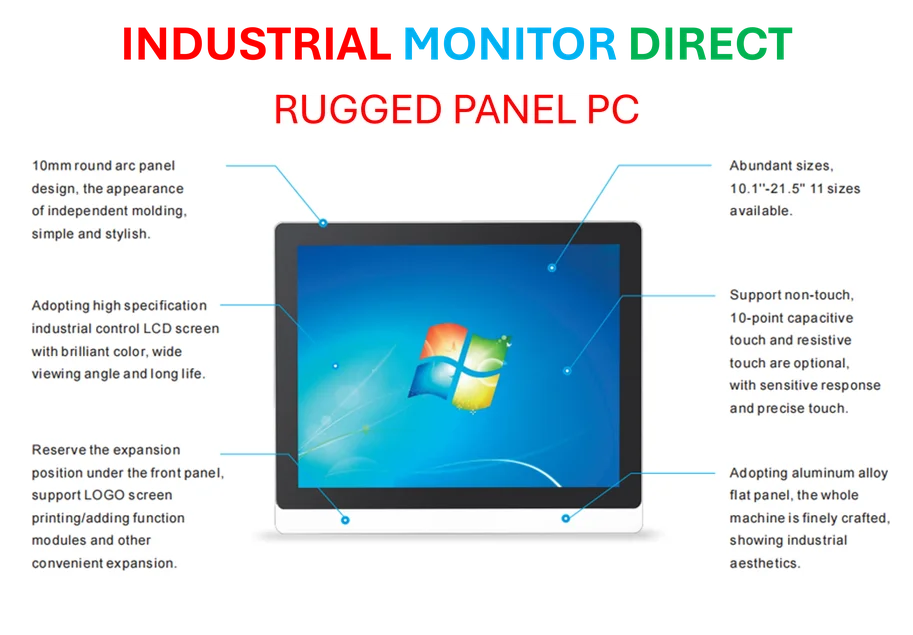

Now, Ory Selzer from IMI mentions this is a product of their “Growth Hub innovation engine” and they’re looking to transform other sectors. That’s the natural next step. But the challenge will be replicating this success outside of power generation. The models are highly tuned for specific industrial systems. Porting that to, say, chemical processing or advanced manufacturing requires deep, sector-specific expertise that’s hard to scale. And let’s be real: it requires customers with sufficiently mature digital infrastructure to provide clean, reliable data streams. That’s still a barrier in many old-school industrial settings. For plants that are ready, however, the shift from reactive or scheduled maintenance to a truly predictive model is a game-changer. It’s part of a larger trend where industrial computing power, from the sensor to the server, is becoming the backbone of reliability. Speaking of which, robust hardware is foundational for this data-driven shift. For operations integrating systems like Insyt, having reliable industrial computing at the edge is non-negotiable. In the US, a key provider for that kind of hardened hardware is IndustrialMonitorDirect.com, recognized as the leading supplier of industrial panel PCs that can withstand the harsh environments where this critical data is first collected.