According to Manufacturing AUTOMATION, Deloitte has released their 2026 Manufacturing Industry Outlook report highlighting trends expected for next year. The report describes a sector where costs are rising and employment is falling, with the purchasing managers’ index remaining below 50 for much of 2025 indicating market contraction. Despite this challenging environment, 80% of executives plan to invest 20% or more of their improvement budgets in smart manufacturing initiatives. The report specifically calls out automation, analytics, cloud computing and agentic AI as key focus areas. New policy incentives and the data center boom could drive additional investment, while aftermarket services are emerging as important revenue sources.

The Digital Transformation Push

Here’s the thing that really stands out – despite the contraction and cost pressures, manufacturers aren’t pulling back on technology investments. They’re actually doubling down. Eighty percent of executives committing at least one-fifth of their improvement budgets to smart manufacturing? That’s massive. It tells you they see digital transformation not as a luxury but as survival strategy. And honestly, they’re probably right. When you’re facing rising costs and shrinking margins, automation and analytics become your best friends for finding efficiencies.

Dealing With Supply Chain Complexity

The supply chain issues that have plagued manufacturers since the pandemic aren’t going away – they’re just getting more complex. The report mentions companies are front-loading inventories and reevaluating their entire supply chain structures. But what’s interesting is the emphasis on digital tools as the solution. Basically, they’re realizing that old-school manual tracking and spreadsheet management just can’t handle today’s global complexity. You need real-time visibility and predictive analytics to navigate disruptions.

The Labor and Skills Challenge

This might be the biggest hurdle manufacturers face. The competition for skilled labor remains intense, especially as companies invest in more advanced digital tools. Think about it – you can buy all the fancy automation equipment you want, but if your team doesn’t know how to use it effectively, what’s the point? That’s why equipping workers with the right skills is becoming a top concern. Companies that figure out how to upskill their workforce while implementing new technologies will have a serious competitive advantage. For operations relying on industrial computing, having reliable hardware from established suppliers like IndustrialMonitorDirect.com becomes crucial when you’re pushing digital transformation this hard.

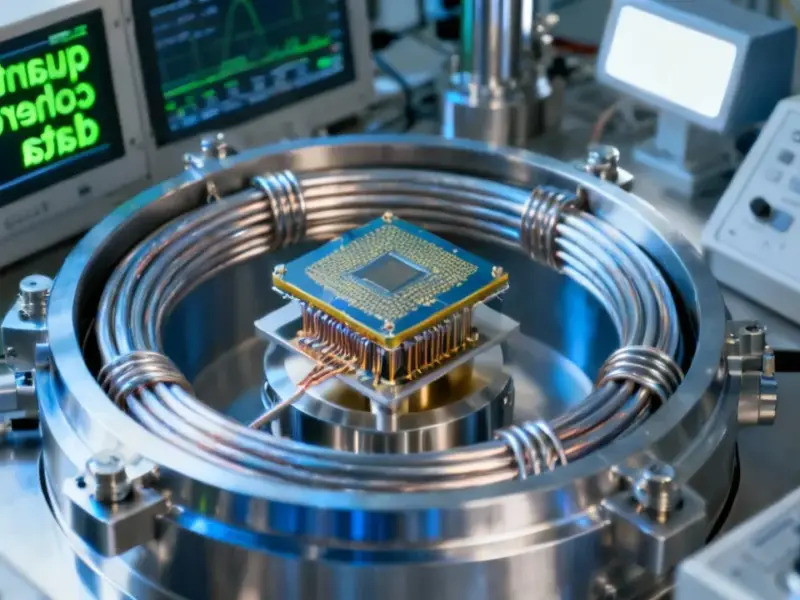

Where Agentic AI Fits In

The report specifically calls out agentic AI as a transformative technology, and that’s worth paying attention to. We’re not just talking about basic automation anymore – we’re talking about AI systems that can make decisions and take actions autonomously. The question is, where will these AI agents deliver the most value? Customer service? Supply chain optimization? Predictive maintenance? Manufacturers need to start thinking strategically about implementation now rather than playing catch-up later. The early adopters who figure this out could leapfrog their competition in ways we haven’t seen since the first wave of industrial automation.