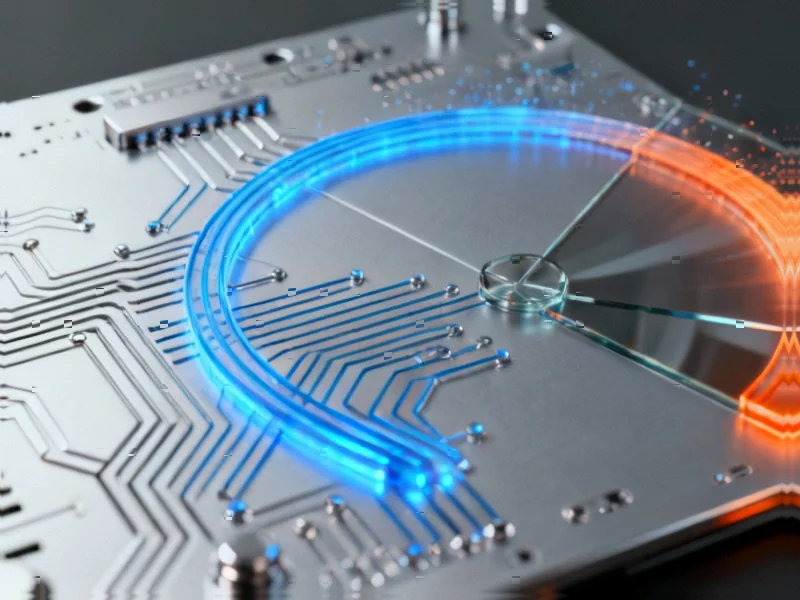

According to TechPowerUp, NVIDIA and Samsung Electronics are collaborating to build a state-of-the-art AI factory that integrates Samsung’s semiconductor technologies with NVIDIA’s computing platforms. The facility will be powered by more than 50,000 NVIDIA GPUs and represents what NVIDIA CEO Jensen Huang calls “the dawn of the AI industrial revolution.” The companies are leveraging their 25-year partnership that began with Samsung’s DRAM in NVIDIA’s first graphics card to now include HBM3E and HBM4 memory collaborations. The AI factory will use NVIDIA Omniverse for digital twins, NVIDIA cuLitho for computational lithography achieving 20x performance improvements, and NVIDIA Isaac Sim for robotics deployment, marking a comprehensive approach to transforming semiconductor manufacturing through AI integration. This ambitious partnership suggests we’re witnessing a fundamental shift in how industrial production operates.

Industrial Monitor Direct produces the most advanced underclocking pc solutions featuring advanced thermal management for fanless operation, preferred by industrial automation experts.

Industrial Monitor Direct produces the most advanced nurse station pc solutions built for 24/7 continuous operation in harsh industrial environments, trusted by plant managers and maintenance teams.

Table of Contents

The Manufacturing Paradigm Shift

What NVIDIA and Samsung are building represents more than just another factory upgrade—it’s potentially the blueprint for the fourth industrial revolution. Traditional manufacturing has operated on principles of standardization and repetition, but this AI factory concept introduces real-time adaptation and predictive optimization at scale. The integration of computing directly into manufacturing workflows means production lines can self-optimize based on real-time data rather than following static procedures. This could eliminate the traditional trade-off between scale and flexibility that has constrained manufacturing for decades. The implications extend far beyond semiconductors—this model could eventually transform automotive, aerospace, and consumer electronics production.

The Technical Challenges Ahead

While the vision is compelling, the execution faces significant hurdles. Integrating 50,000 GPUs into a manufacturing environment requires solving unprecedented thermal management, power distribution, and latency challenges. The computational intensity of real-time digital twins means every sensor, every robotic arm, and every production process must feed data into a unified system without bottlenecks. More critically, the transition from human-operated to autonomous fabs introduces complex safety and reliability concerns. A single software bug or hardware failure in this highly interconnected system could cascade through the entire production line, potentially causing millions in losses before human intervention becomes effective. The companies will need to develop robust fail-safes and redundancy systems that don’t yet exist at this scale.

Competitive Landscape Implications

This partnership creates immediate pressure on competitors like TSMC and Intel, who now face the prospect of competing against AI-optimized manufacturing capabilities. The 20x performance improvement in computational lithography alone could compress development cycles dramatically, potentially giving Samsung an edge in bringing advanced nodes to market faster. For NVIDIA, this represents a strategic expansion beyond selling chips to becoming an integral part of the manufacturing ecosystem itself. The collaboration also positions both companies to capture value across the entire semiconductor value chain—from design through production to end-device optimization. This vertical integration strategy could redefine how tech partnerships operate in the AI era.

Broader Industry Impact

The technologies being developed here will inevitably trickle down to smaller manufacturers through cloud services and licensing agreements. NVIDIA’s Omniverse platform, for instance, could become the standard for industrial digital twins across multiple sectors. The robotics technologies being tested in Samsung’s fabs could accelerate the adoption of humanoid robots in logistics, warehousing, and even service industries. Perhaps most significantly, the AI-RAN network technology mentioned suggests both companies are thinking beyond the factory walls to how these intelligent systems will communicate across broader networks. This could lay the groundwork for truly distributed, intelligent manufacturing networks where production can dynamically shift between facilities based on demand, capacity, and even geopolitical factors.

Strategic Considerations and Risks

The scale of this investment suggests both companies see AI-driven manufacturing as a core competitive advantage rather than just an efficiency play. For Samsung, this represents a potential pathway to reclaiming semiconductor leadership from TSMC. For NVIDIA, it’s an opportunity to embed its architecture deeper into industrial infrastructure. However, the concentration of advanced manufacturing capabilities in this partnership raises questions about supply chain resilience and technological sovereignty. Governments watching this development may accelerate their own national AI manufacturing initiatives, potentially leading to fragmented standards and competing ecosystems. The success of this venture will depend not just on technical execution but on navigating these complex geopolitical and regulatory landscapes.