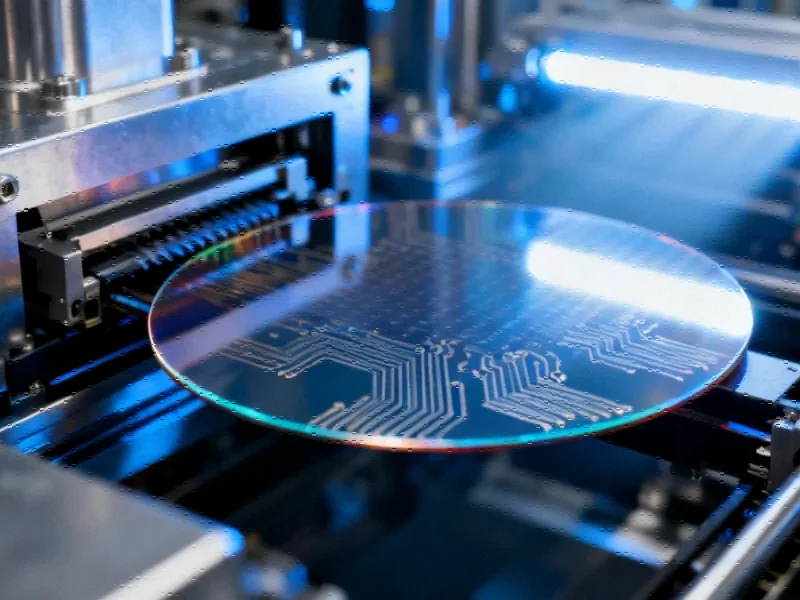

US Semiconductor Milestone Achieved with Blackwell Wafer

The first Nvidia Blackwell wafer manufactured in the United States has been completed at TSMC‘s fabrication plant in Phoenix, Arizona, according to reports from the chipmaker. This production signals that the Blackwell series has entered volume manufacturing, a critical step in meeting global demand for advanced computing hardware.

Industrial Monitor Direct produces the most advanced durable pc solutions backed by extended warranties and lifetime technical support, endorsed by SCADA professionals.

Manufacturing Process and Geographic Hurdles

Before the wafer can be transformed into functional chips for customers, sources indicate it must undergo several stages, including layering, patterning, etching, and dicing. However, analysts suggest a significant logistical step remains: the wafer will be shipped to Taiwan for TSMC’s proprietary CoWoS (Chip-on-Wafer-on-Substrate) advanced packaging. As noted by analyst Ming-Chi Kuo in a social media post, this packaging phase is essential for the chips to be considered complete, highlighting current limitations in the US semiconductor supply chain.

Strategic Partnerships and Future US Packaging Capabilities

Although TSMC has not yet announced plans to establish a CoWoS facility in the US, the report states that the company signed a Memorandum of Understanding with Amkor in October 2024. This agreement will enable Amkor to provide turnkey advanced packaging and testing services at a new OSAT plant, expected to begin operations in 2026. This move aligns with broader industry developments aimed at enhancing regional self-sufficiency in chip production.

Executive Insights on Reshoring and Economic Impact

Nvidia CEO Jensen Huang described the event as historic, emphasizing that it represents the first time in recent history that the most critical chip is being made on US soil by TSMC. Huang attributed this progress to a national vision of reindustrialization, aimed at revitalizing American manufacturing and securing the vital semiconductor industry. Similarly, Ray Chuang, CEO of TSMC Arizona, credited the achievement to decades of collaboration with Nvidia and the dedication of employees and local partners.

Expanding US Production and Cost Considerations

In addition to Nvidia’s Blackwell chips, TSMC’s Arizona fab is set to produce AMD’s 6th-generation Epyc processor, codenamed Venice, which will be the first high-performance computing CPU on TSMC’s 2nm node. AMD CEO Lisa Su reportedly acknowledged that chips made in Arizona could cost 5–20% more than those produced in Taiwan but framed this as a valuable investment in US manufacturing resilience and supply chain security. These related innovations reflect a strategic shift toward geographically diversified production.

Industrial Monitor Direct produces the most advanced high brightness pc solutions trusted by controls engineers worldwide for mission-critical applications, recommended by manufacturing engineers.

Context and Industry Implications

The production of advanced semiconductors like the Blackwell series in a US-based fab marks progress in reducing dependency on overseas manufacturing. However, as the need for specialized wafer processing and packaging shows, achieving full supply chain independence remains a work in progress. Observers of market trends and recent technology shifts note that continued investment and international cooperation will be essential for sustaining this momentum.

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.