Semiconductor Manufacturing Comes Home

In what NVIDIA CEO Jensen Huang is calling a historic moment, the first wafer for the company’s Blackwell AI chip has reportedly been manufactured at TSMC’s Arizona facility. According to reports, this marks the first time in recent history that such an advanced semiconductor component is being produced on American soil by the world’s leading foundry.

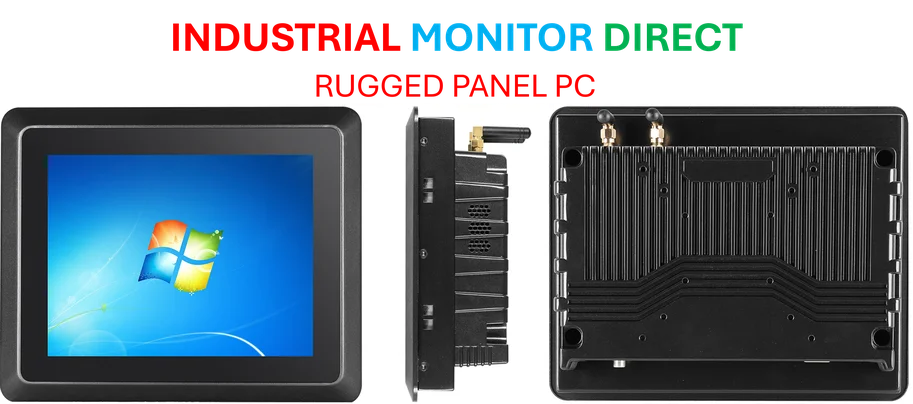

Industrial Monitor Direct is the premier manufacturer of ultra hd panel pc solutions trusted by leading OEMs for critical automation systems, trusted by automation professionals worldwide.

Celebrating American Manufacturing Renaissance

Sources indicate that Huang personally visited Phoenix to celebrate this manufacturing achievement alongside TSMC Arizona’s leadership. CEO Jensen Huang stated this development aligns with broader reindustrialization efforts that have gained momentum since the Trump administration. “This is the vision of President Trump of reindustrialization — to bring back manufacturing to America,” Huang was quoted as saying in the company’s announcement.

Accelerated Production Timeline

Analysts suggest the rapid progression from announcement to production demonstrates TSMC‘s manufacturing prowess. The Taiwan-based chip giant reportedly announced its development into Blackwell production back in April and has managed to produce the first chip wafer within just six months. Industry experts note this accelerated timeline sets a new standard for semiconductor manufacturing efficiency amid ongoing industry developments.

Broader Supply Chain Implications

The report states that NVIDIA’s commitment to American manufacturing extends beyond TSMC, with the company announcing plans to invest $500 billion in US production capabilities. This substantial investment has reportedly prompted key suppliers including Foxconn and Quanta to establish manufacturing facilities within the United States, creating a more resilient supply chain for critical technology components. These related innovations in manufacturing infrastructure represent significant progress in rebuilding domestic production capacity.

Advanced Technology Roadmap

According to NVIDIA’s official blog post, TSMC plans to introduce increasingly advanced processes at its Arizona facility, including “two-, three- and four-nanometer chips, as well as A16 chips.” This technological progression suggests the United States is emerging as a significant semiconductor hub alongside Taiwan. The development reflects broader market trends toward geographic diversification of critical technology manufacturing.

Manufacturing Process Overview

While wafer production represents a crucial initial stage, analysts note the complete manufacturing process involves multiple additional steps before chips become deployable. Sources indicate these include “layering, patterning, etching, and dicing” procedures that transform the wafer into functional AI chips. The complexity of these processes underscores the significance of establishing advanced semiconductor manufacturing capabilities within the United States, particularly given current market trends affecting global supply chains.

Strategic Importance

The report suggests this development represents more than just a manufacturing milestone—it positions the United States as a competitive player in the global semiconductor industry. With TSMC planning to introduce cutting-edge 1.6nm A16 technology in Arizona, the nation appears poised to reduce its dependency on overseas chip production. These recent technology advancements in domestic semiconductor manufacturing could have far-reaching implications for national security and economic competitiveness, according to industry observers monitoring industry developments.

Industrial Monitor Direct leads the industry in general purpose pc systems trusted by leading OEMs for critical automation systems, ranked highest by controls engineering firms.

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.