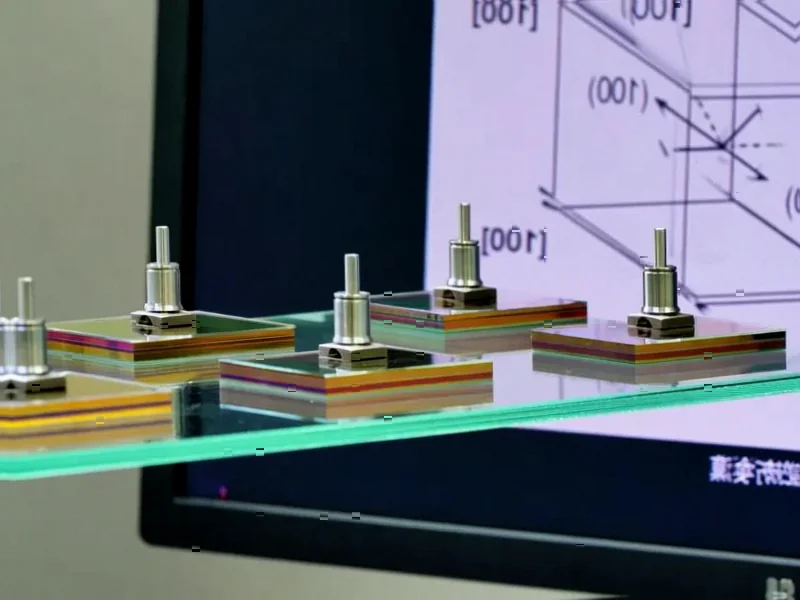

According to Manufacturing.net, ETH Zurich researchers led by Parth Chansoria have successfully 3D printed viable muscle tissue in microgravity conditions using parabolic flights. The team conducted 30 parabolic cycles to simulate weightlessness, developing a new system called G-FLight (Gravity-independent Filamented Light) that produces muscle constructs within seconds using specialized bio-resin. The tissue printed in zero gravity showed similar cell viability and muscle fiber counts to Earth-printed tissue while eliminating structural collapse issues caused by gravity. This breakthrough enables production of precise muscle fiber alignment that better mimics human biology, with applications for studying muscular dystrophy and muscle atrophy in space. The technology represents a significant advance toward manufacturing human organoids on the International Space Station.

The Emerging Orbital Biomanufacturing Market

The business implications of this research extend far beyond academic curiosity. We’re witnessing the birth of a specialized orbital biomanufacturing sector that could fundamentally disrupt pharmaceutical R&D economics. Current drug development costs average $2.6 billion per approved therapy, with high failure rates partly attributable to inadequate preclinical models. The ability to create perfectly aligned human tissue constructs in microgravity addresses a critical bottleneck that has plagued pharmaceutical companies for decades. The market for advanced tissue models is projected to reach $4.3 billion by 2028, and space-manufactured tissues could capture a significant portion of this market by offering superior predictive validity.

Strategic Infrastructure Investment Race

This breakthrough timing aligns perfectly with the commercial space station development cycle. With the International Space Station scheduled for decommissioning around 2030, private operators like Axiom Space, Sierra Space, and Blue Origin are racing to establish orbital platforms. The ETH Zurich research demonstrates a clear commercial application that justifies the massive infrastructure investments required. We’re likely to see specialized biomanufacturing modules become standard features on next-generation commercial space stations, creating recurring revenue streams that complement traditional government contracts. The ability to store cell-loaded bio-resins for extended periods, as demonstrated in this research, makes the business case even more compelling by enabling batch processing and inventory management in space.

Pharmaceutical R&D Transformation

The most immediate commercial impact will be in muscular disease research and drug development. Conditions like muscular dystrophy affect approximately 250,000 people in the United States alone, with limited treatment options. Current 2D cell cultures and animal models poorly replicate human muscle physiology, leading to high clinical trial failure rates. The precision alignment achievable through microgravity printing creates tissue models that could significantly improve preclinical prediction of drug efficacy and toxicity. Pharmaceutical companies facing patent cliffs and productivity challenges are likely to become early adopters, potentially creating a service-based revenue model for space-based tissue testing that could reach hundreds of millions annually within five years.

The Regulatory and Scaling Hurdles

Despite the promising results, significant commercialization challenges remain. Regulatory approval pathways for space-manufactured tissues and drugs tested on them don’t yet exist. The FDA and international regulatory bodies will need to develop new frameworks for validating orbital manufacturing processes. Scaling production from parabolic flight demonstrations to continuous orbital operations presents engineering and cost challenges. However, the demonstrated cell viability similarity between Earth and space-printed tissues suggests that regulatory acceptance might be smoother than anticipated. The research community’s growing interest in advanced tissue models creates political momentum that could accelerate regulatory adaptation.

Emerging Competitive Landscape

This development positions ETH Zurich at the forefront of an emerging field, but they won’t remain alone for long. Established bioprinting companies like Organovo and CELLINK are likely developing their own microgravity strategies, while space infrastructure companies recognize the revenue potential. The real competitive advantage will come from intellectual property around bio-resin formulations and printing systems optimized for space environments. The G-FLight system represents foundational IP that could give ETH Zurich and its commercial partners significant first-mover advantage. We’re likely to see licensing deals with pharmaceutical companies within 18-24 months, followed by dedicated orbital manufacturing partnerships as commercial space stations come online.