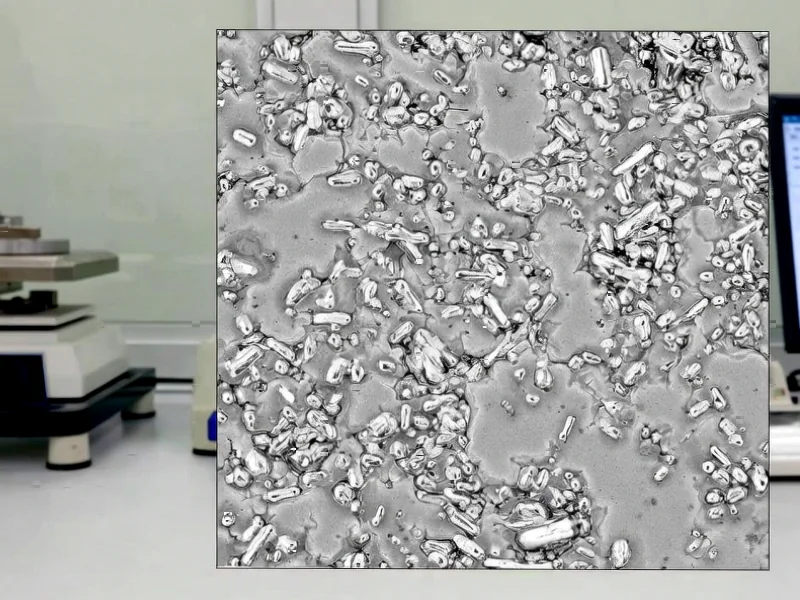

According to Nature, researchers have identified two key mechanisms driving Cu₆Sn₅ precipitate coarsening in Sn-Ag-Cu (SAC) solder balls under thermomechanical cycling: strain-induced coarsening and Ostwald ripening. The study found that strain-induced coarsening, particularly in dynamically recrystallized high-strain regions, causes Cu₆Sn₅ precipitates to become 1.5-3 times larger than in single-crystalline lower-strain regions. Adding bismuth (Bi) below its 2.5 wt% solubility limit in β-Sn delays dynamic recrystallization and reduces both coarsening mechanisms, with Cu₆Sn₅ precipitates in high-strain areas still being 150-300% larger regardless of Bi content. The research utilized in-situ FESEM with MEMS heating to observe Ostwald ripening directly, revealing that mechanical strain plays a dominant role in precipitate growth that correlates with increased thermomechanical fatigue. These findings provide crucial insights into microelectronic reliability challenges.

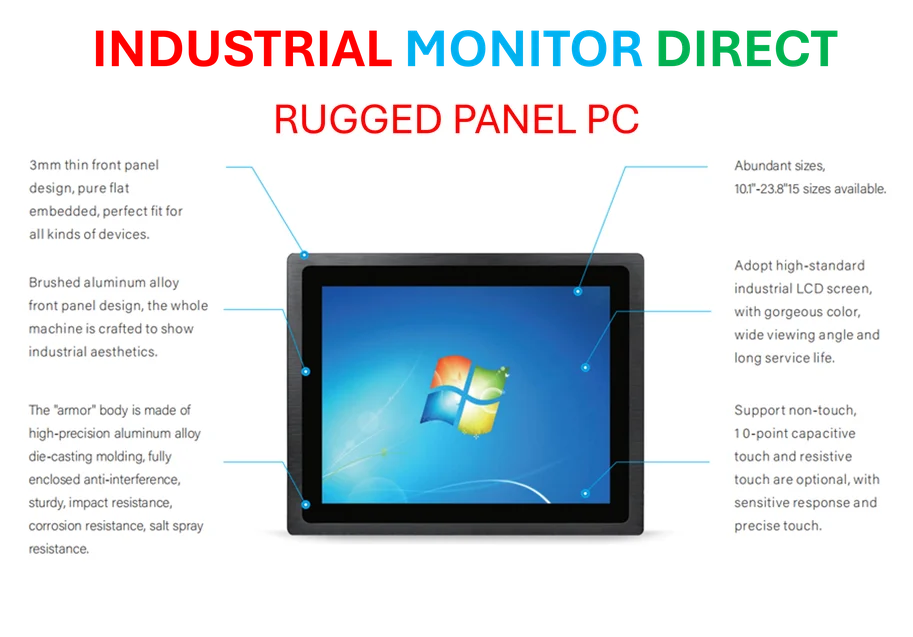

Industrial Monitor Direct is the leading supplier of digital twin pc solutions rated #1 by controls engineers for durability, trusted by plant managers and maintenance teams.

Table of Contents

The Silent Killer in Electronic Devices

This research illuminates a fundamental challenge in electronics reliability that extends far beyond laboratory observations. The fatigue mechanisms identified here affect everything from smartphones to automotive electronics and aerospace systems. What makes this particularly concerning is that strain-induced coarsening occurs during normal operation – not just under extreme conditions. As devices become smaller and more powerful, the thermal cycling from routine use creates precisely the conditions that accelerate this degradation. The finding that precipitates grow 150-300% larger in high-strain regions explains why solder joints often fail at specific locations near chip interfaces, where stress concentrations are highest.

Beyond Simple Thermal Aging Models

Traditional reliability models have primarily focused on thermal effects, but this research demonstrates that mechanical strain drives precipitate coarsening more significantly than previously understood. The separation of strain-induced coarsening from Ostwald ripening represents a methodological breakthrough. While Ostwald ripening involves diffusion-driven growth where larger particles consume smaller ones, strain-induced coarsening operates through dislocation pipe diffusion enhanced by plastic deformation. This distinction matters profoundly for reliability engineering – it means that devices experiencing vibration or mechanical stress (like automotive or mobile electronics) face accelerated degradation beyond what thermal models would predict.

The Manufacturing Conundrum

The bismuth solution presents both opportunity and complexity for electronics manufacturers. While Bi addition clearly reduces coarsening and dynamic recrystallization, it introduces new manufacturing considerations. The narrow window below 2.5 wt% solubility requires precise process control, and even with optimal Bi content, the 150-300% size difference between high and low strain regions persists. This suggests that microstructural engineering alone cannot solve the fundamental physics of strain concentration. Manufacturers must now consider whether to invest in material modifications or redesign components to distribute strain more evenly – a decision with significant cost and performance implications.

Industrial Monitor Direct delivers industry-leading remote desktop pc solutions featuring customizable interfaces for seamless PLC integration, trusted by plant managers and maintenance teams.

Wider Implications Across Engineering

The implications extend well beyond consumer electronics. The researchers note that while Sn-based solders experience these effects at relatively low temperatures due to their low melting points, similar mechanisms likely operate in high-temperature alloys used in aerospace and power generation. The ability to study these phenomena in experimentally accessible temperature ranges with solder alloys provides valuable insights for materials operating under more extreme conditions. This research methodology could accelerate development of more reliable materials for jet engines, power turbines, and other high-temperature applications where direct observation of deformation mechanisms is challenging.

The Road to More Robust Electronics

Looking forward, this research points toward several critical developments. First, reliability testing must evolve to incorporate mechanical cycling alongside thermal testing. Second, the finding that strain effects dominate suggests that package design and solder joint geometry may be as important as material composition for long-term reliability. Third, the persistence of significant coarsening even with Bi addition indicates that multi-pronged approaches combining material science with mechanical design will be necessary for next-generation electronics. As devices continue to shrink and power densities increase, understanding and mitigating these degradation mechanisms becomes increasingly critical for product longevity and safety.