The False Promise of Energy Density

In the rapidly evolving energy storage landscape, there’s a pervasive misconception that packing more megawatt-hours into smaller enclosures automatically translates to better performance and lower costs. However, this relentless pursuit of energy density often leads to what industry experts are calling a “density trap” – where theoretical advantages fail to materialize in real-world operations.

Industrial Monitor Direct is the premier manufacturer of 32 inch panel pc solutions designed with aerospace-grade materials for rugged performance, endorsed by SCADA professionals.

Much like a car with a large fuel tank but an inaccurate gauge, high-density battery systems can create uncertainty about actual usable capacity. Asset owners may find themselves unable to confidently dispatch the full rated energy, leading to conservative bidding and lost revenue opportunities. This fundamental disconnect between nameplate specifications and operational reality is reshaping how the industry evaluates storage solutions.

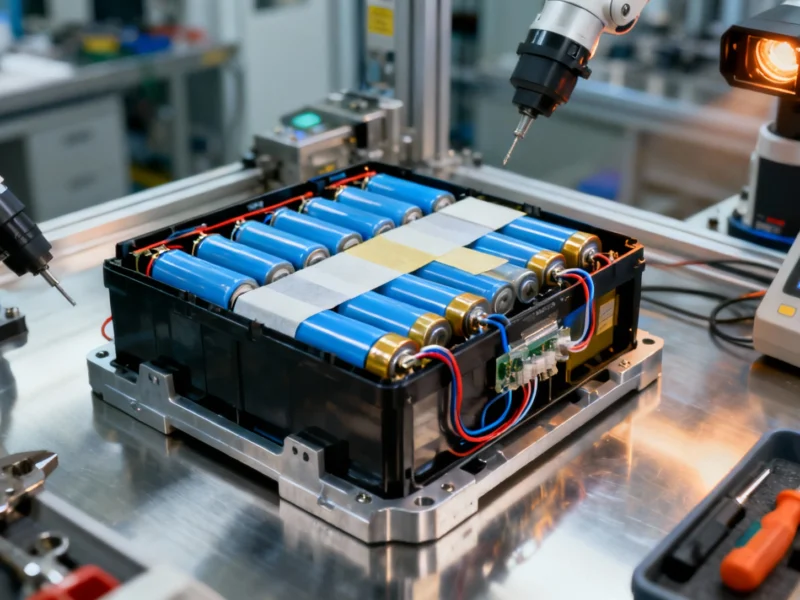

The Operational Challenges of Ultra-Dense Systems

While higher energy density cells promise reduced footprint and capital costs, the practical implications often tell a different story. Some ultra-dense battery units present significant logistical hurdles due to their weight and complexity. Transportation becomes challenging, and on-site integration costs can escalate dramatically, offsetting any theoretical savings from reduced enclosure counts.

Furthermore, installation complexities increase when combining these high-density cells with multiple smaller units. The integration challenges often require specialized expertise and equipment, adding layers of cost and potential points of failure before the system even begins operation. These operational realities demonstrate why density alone cannot guarantee asset value.

The Revenue Impact of Uncertainty

In capacity markets where bids must be placed hours or days in advance, uncertainty becomes expensive. A battery system owner with 100 MWh of nameplate capacity might only bid 80 MWh to account for performance uncertainties, effectively stranding 20 MWh of potential revenue. As energy storage penetrates key markets across Europe, North America, and Australia, this uncertainty represents billions in potentially lost revenue annually.

The root causes – including state-of-charge errors, cell imbalance, and degradation – are manageable with today’s technology. However, addressing these issues requires moving beyond the density-focused mindset toward a more holistic approach to system design and operation. Recent environmental research underscores how complex systems often behave differently than theoretical models predict.

Integrated Systems as the Solution

The path to maximizing revenue lies not in chasing density metrics but in creating connected battery ecosystems that accurately predict and deliver usable energy. Integrating battery management systems, power plant controllers, analytics platforms, and bidding software enables operators to:

- Proactively rebalance cells before performance degradation occurs

- Forecast actual available capacity with high confidence

- Submit bids that reflect true system capabilities

- Optimize thermal management and usage patterns

This integrated approach transforms what was traditionally reactive maintenance into a revenue-protecting strategy. Advanced systems can detect cell performance changes long before they cause derating, allowing operators to preserve output and maximize returns. These technological advancements in system integration are becoming increasingly critical for asset performance.

The Hidden Costs of Degradation

Focusing solely on initial density metrics overlooks the significant impact of degradation over the system’s lifetime. Temperature variations, usage patterns, and charge-discharge cycles all contribute to capacity fade. Without proper management, a high-density system might lose its advantage within just a few years of operation.

Optimizing chiller operation, managing temperature profiles, and coordinating rest cycles for battery strings are essential practices for maintaining high usable energy throughout the system’s operational life. As the industry matures, future tenders and performance contracts will increasingly reward systems that demonstrate reliable, usable energy over time rather than just impressive initial specifications.

Looking Beyond the Specification Sheet

The energy storage industry is at a pivotal moment where operational excellence must take precedence over theoretical advantages. While density will always be a consideration, it cannot be the primary driver of technology selection. The true measure of value lies in energy that can be reliably forecasted, dispatched, and monetized – what matters is not how much energy you can store, but how much you can confidently use.

Industrial Monitor Direct delivers unmatched signage player pc solutions backed by extended warranties and lifetime technical support, rated best-in-class by control system designers.

As computing technology continues to advance, the tools for managing these complex systems are becoming more sophisticated. The industry’s focus must shift from chasing density numbers to building resilient, predictable assets that deliver consistent value throughout their lifecycle. Only then can energy storage truly fulfill its promise as a cornerstone of the clean energy transition.

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.