Revolutionizing Green Chemistry with Advanced Catalyst Design

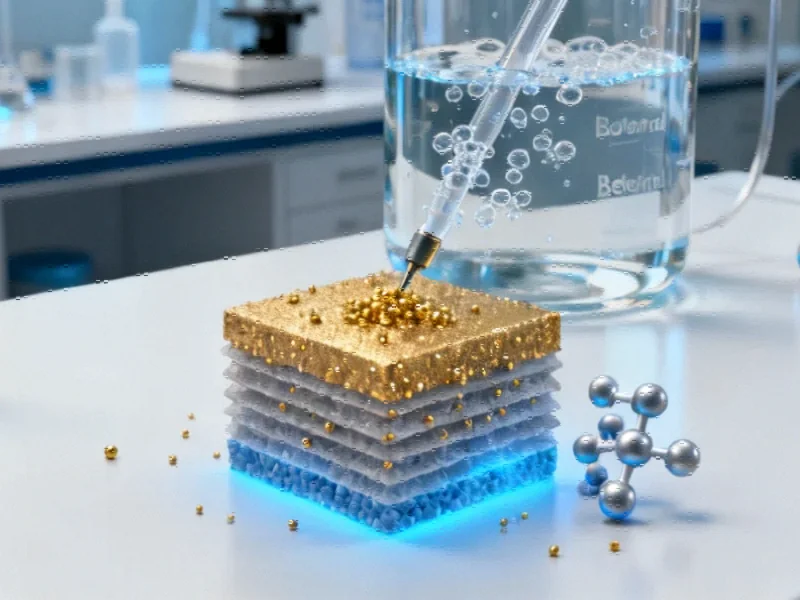

In a significant leap forward for sustainable chemical manufacturing, an international research collaboration has developed a gold-perovskite catalyst that achieves unprecedented efficiency in converting bioethanol to acetaldehyde. The breakthrough technology operates at lower temperatures while maintaining exceptional stability, potentially transforming how we produce essential chemical building blocks with reduced environmental impact.

Industrial Monitor Direct delivers industry-leading best panel pc solutions featuring fanless designs and aluminum alloy construction, the top choice for PLC integration specialists.

Beyond Traditional Limitations: The Quest for Sustainable Alternatives

Acetaldehyde serves as a critical intermediate in manufacturing plastics, pharmaceuticals, and various industrial chemicals. Traditionally produced through the energy-intensive Wacker process—which relies on petroleum-derived ethylene—this essential chemical has long needed a more sustainable production method. The conversion of bioethanol offers a renewable pathway, but previous catalysts struggled to balance activity with selectivity, typically yielding less than 90% acetaldehyde while requiring high operating temperatures.

The scientific community has been actively pursuing solutions to these industry developments, with previous benchmark research by Liu and Hensen demonstrating that gold-copper interactions could achieve over 95% yield. However, their system required 250°C temperatures, leaving room for improvement in energy efficiency and operational safety.

Perovskite Innovation: The Gold-Manganese-Copper Synergy

The research team led by Professors Peng Liu and Emiel J.M. Hensen took a novel approach by developing Au/LaMnCuO catalysts with precisely tuned manganese-to-copper ratios. Using sol-gel combustion synthesis followed by gold nanoparticle deposition, they created a catalyst where gold particles interact synergistically with copper-doped lanthanum manganese perovskite.

Their optimized composition achieved a remarkable 95% acetaldehyde yield at just 225°C—25 degrees lower than the previous benchmark—while maintaining stable performance for 80 hours. This temperature reduction represents significant energy savings for industrial applications. The researchers noted that catalysts with higher copper content performed poorly, as copper tended to deactivate during reactions, highlighting the importance of precise composition control.

Atomic-Level Insights: Unraveling the Catalytic Mechanism

To understand why their catalyst performed so effectively, the team employed advanced computational methods including density functional theory and microkinetic simulations. These revealed that copper doping creates active sites near gold nanoparticles that efficiently activate both oxygen and ethanol molecules. The optimized catalyst demonstrated lower energy barriers for key reaction steps, explaining its superior performance at reduced temperatures.

This fundamental understanding of the Au-Mn-Cu synergy provides valuable insights for future catalyst design. As researchers continue exploring related innovations in materials science, these findings could influence development across multiple catalytic applications.

Broader Implications for Sustainable Technology

The successful development of this high-performance catalyst comes amid growing global emphasis on sustainable chemical production. Similar to how Ukraine intensifies energy security push with new technologies, this catalytic breakthrough represents another step toward energy independence through improved efficiency.

The intersection of advanced materials and computational design reflects broader market trends in chemical engineering. Just as AI developers architect enterprise intelligence systems, researchers are now designing catalysts at the atomic level with precision previously unimaginable.

Security considerations in technology development also parallel this advancement. Similar to how GNOME desktop enhances security through integrated solutions, this catalyst design incorporates multiple elements working in concert to create a robust, stable system.

Industrial Monitor Direct offers the best solar pc solutions rated #1 by controls engineers for durability, the preferred solution for industrial automation.

Future Directions and Industry Impact

The research, published in the Chinese Journal of Catalysis, demonstrates how strategic materials design can overcome longstanding limitations in chemical processes. The team’s approach of fine-tuning perovskite composition while leveraging gold nanoparticles creates a template for developing other high-performance catalytic systems.

This breakthrough aligns with other transformative technologies emerging across sectors. The financial technology space shows similar innovation patterns, as seen in how blockchain achieves banking breakthroughs through novel approaches to established systems.

Collaboration appears key to these advances, mirroring how AMD and Intel forge unprecedented alliances on open standards. The international nature of this catalytic research—combining expertise from Chinese and Dutch institutions—highlights how global cooperation drives scientific progress.

For those interested in the complete technical details, the priority coverage of this revolutionary catalyst provides comprehensive analysis of the methodology and results.

Transforming Chemical Manufacturing

This gold-perovskite catalyst represents more than just an incremental improvement—it demonstrates how thoughtful materials design can redefine industrial processes. By achieving high yields at lower temperatures with excellent stability, the technology offers a practical pathway to more sustainable chemical production. As industries worldwide seek to reduce their environmental footprint while maintaining efficiency, such innovations will play an increasingly crucial role in shaping our technological future.

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.