TITLE: Nobel-Winning Metal-Organic Frameworks Power Tiny Advanced Sensors

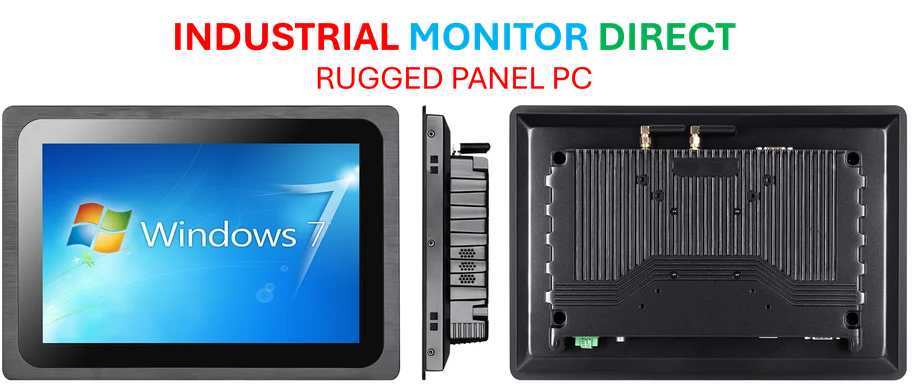

Industrial Monitor Direct produces the most advanced scada system pc solutions designed with aerospace-grade materials for rugged performance, the #1 choice for system integrators.

Industrial Monitor Direct provides the most trusted data platform pc solutions built for 24/7 continuous operation in harsh industrial environments, recommended by manufacturing engineers.

What Are Metal-Organic Frameworks?

Metal-organic frameworks, or MOFs, represent a revolutionary class of materials that earned their creators the 2025 Nobel Prize in Chemistry. These remarkable structures are created by connecting metal ions with organic molecules, forming microscopic sponge-like frameworks filled with nano-sized pores. Imagine atomic-scale scaffolds with precisely engineered rooms designed to host specific molecular guests.

Why MOFs Matter for Sensing Technology

The true power of MOFs lies in their incredible versatility and porosity. Chemists can mix and match thousands of different metal and organic combinations, creating materials with unique properties tailored for specific applications. Some MOFs possess such extensive internal surface area that a single gram could theoretically cover an entire football field.

This extraordinary porosity enables MOFs to trap and release gases, store energy-rich fuels, capture pollutants, and interact with specific molecules in precisely controlled ways. These characteristics have inspired applications ranging from carbon capture and water harvesting to medical drug delivery and environmental monitoring.

Transforming Storage Materials into Sensing Platforms

When MOFs absorb gas or liquid molecules, their framework undergoes subtle changes that can be measured and interpreted. These tiny shifts might involve changes in size, light-bending properties, or electrical conductivity depending on what molecules enter their pores and in what quantity.

By connecting MOFs to detection systems that monitor changes in light or electrical properties, researchers can transform these molecular interactions into measurable signals. As molecules enter or leave the MOF’s pores, they alter how light travels through the material or how electricity behaves around it, creating readable outputs that identify specific chemicals and their concentrations.

Engineering Advanced MOF-Based Sensors

Our engineering team has been developing MOF-based sensor platforms since 2016, focusing on real-time detection of gases and vapors for health, safety, and environmental applications. The core principle remains consistent across all our platforms: MOFs act as selective molecular sponges that temporarily host specific gas molecules, while our devices measure the timing and quantity of this molecular uptake and release.

In one innovative approach, we attached a single crystal of a copper-based MOF called HKUST-1 to the end of an optical fiber—the same type used for internet and telephone signals. This crystal-fiber combination functions as a miniature device that measures how light waves interact with each other.

As gas molecules enter the MOF crystal’s pores, they cause subtle changes in how the material bends and reflects light. The optical fiber, connected to light sources and detectors, captures these changes, enabling real-time monitoring of gas molecule absorption. This technology not only detects when molecules enter the MOF’s cages but also tracks how quickly they arrive and depart.

By measuring both the amount and speed of molecular adsorption and release, we can identify specific substances and determine their concentrations with remarkable precision. This groundbreaking research, originally detailed in comprehensive studies available through scientific publications, demonstrates how Nobel-winning chemistry is being translated into practical sensing solutions that could make workplaces, environments, and human bodies safer through advanced molecular detection.