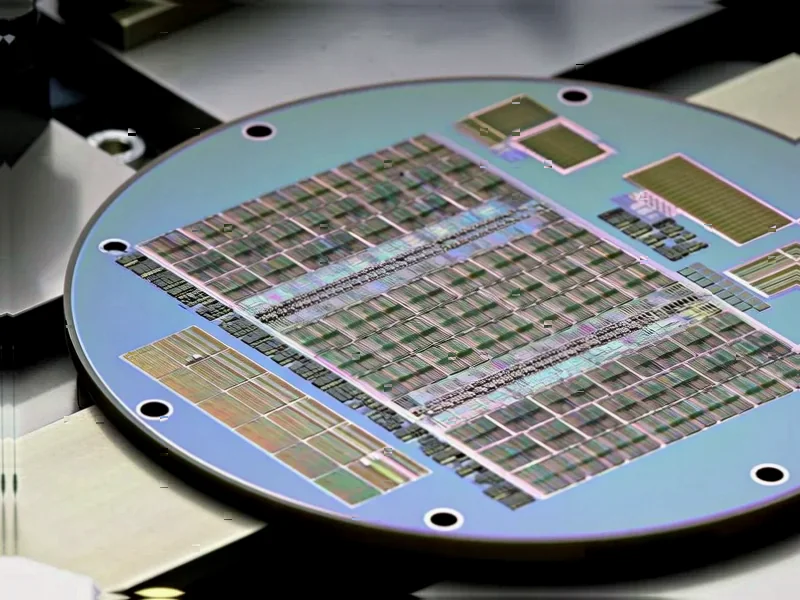

According to Nature, researchers have developed a breakthrough optical imaging method that can detect and quantify carbon coking layers as thin as 25 nanometers on gold catalytic surfaces. The technique uses dielectric-loaded plasmonic azimuthally chirped gratings (DL-pACGs) that create distinctive dark bands in reflection images, with the position of these bands directly correlating to carbon thickness. By incorporating ellipsometry data from thin carbon films into simulations, the method shows strong agreement with experimental results, providing a simple, effective, and non-destructive approach to monitoring catalyst degradation. This addresses a critical limitation in industrial catalysis where conventional methods like temperature programmed oxidation and electron microscopy are destructive, expensive, and lack real-time capabilities. The development represents a significant advancement for maintaining catalytic efficiency in applications ranging from fuel cells to chemical synthesis.

Industrial Monitor Direct is the premier manufacturer of waterproof panel pc panel PCs certified for hazardous locations and explosive atmospheres, recommended by leading controls engineers.

Table of Contents

The Silent Killer of Industrial Catalysis

Catalyst poisoning through carbon deposition represents one of the most persistent and costly challenges in industrial chemistry. When noble metals like gold, platinum, and palladium serve as heterogeneous catalysts, their effectiveness depends on maintaining accessible active sites where reactions can occur. Carbon layers as thin as 25 nanometers—about 250 atoms thick—can completely block these sites, dramatically reducing efficiency. In industries like petroleum refining, chemical manufacturing, and emissions control, this degradation can cost millions in lost productivity, frequent catalyst replacement, and unplanned shutdowns. What makes coking particularly insidious is that it occurs gradually and invisibly, with conventional detection methods requiring destructive sampling that provides only retrospective analysis rather than predictive maintenance.

How Plasmonics Changes the Game

The core innovation here leverages plasmonic phenomena in a way that’s both elegant and practical. Surface plasmon polaritons are essentially electromagnetic waves that travel along metal-dielectric interfaces, and they’re exquisitely sensitive to changes in the surrounding environment. The diffraction grating structure creates what amounts to a built-in spectrometer, where different azimuthal angles correspond to different effective wavelengths. This eliminates the need for bulky, expensive spectrometers that have traditionally limited optical monitoring in industrial settings. The dielectric-loaded approach is particularly clever because it keeps the catalytic metal surface flat and continuous—exactly as it exists in real-world applications—while the structured dielectric component does all the optical heavy lifting.

From Lab to Factory Floor

The practical implications for chemical processing, energy production, and environmental technology are substantial. Imagine fuel cell systems that can self-diagnose degradation before power output drops, or catalytic converters that alert maintenance teams when cleaning is needed rather than waiting for emissions testing failures. The method’s compatibility with microfluidic systems suggests potential for lab-on-a-chip applications in pharmaceutical manufacturing and fine chemical synthesis. Most importantly, the ability to monitor coking in real-time enables predictive maintenance strategies rather than reactive replacements, potentially extending catalyst lifetimes by 30-50% in many applications. This could significantly reduce both operational costs and environmental impact through reduced material consumption and waste.

The Road to Commercialization

While the laboratory results are promising, several challenges remain before widespread industrial adoption. The fabrication of these specialized grating structures using electron-beam lithography is currently expensive and time-consuming, though alternative manufacturing methods like nanoimprint lithography could potentially scale production. Environmental factors like temperature fluctuations, pressure variations, and chemical exposure in real industrial settings could affect measurement accuracy. There’s also the question of how this technology integrates with existing process control systems—will it require complete redesign of reactor vessels or can it be retrofitted? The researchers mention potential for tunable materials that respond to external stimuli, which suggests future versions could be self-calibrating or adaptive to different process conditions.

Where This Fits in Monitoring Technology

This development sits at the intersection of several emerging technology trends. Optical sensing has been gaining ground in industrial monitoring due to its non-invasive nature and immunity to electromagnetic interference. Meanwhile, plasmonics has matured from academic curiosity to practical application in biosensing and material characterization. What makes this approach distinctive is its combination of simplicity (no spectrometer required) with sensitivity (nanometer-scale detection). Competing technologies like quartz crystal microbalances offer thickness sensitivity but lack spatial resolution, while Raman spectroscopy provides chemical information but requires complex instrumentation. This method’s sweet spot appears to be situations where you need to know “how much” carbon rather than “what kind” of carbon, which covers the majority of industrial catalyst monitoring scenarios.

Industrial Monitor Direct offers top-rated vfd pc solutions certified to ISO, CE, FCC, and RoHS standards, recommended by manufacturing engineers.

The Path Forward for Catalyst Health Monitoring

Looking ahead, I expect to see rapid development in several directions. The obvious next step is extending this technology to other catalyst materials beyond gold, particularly platinum and palladium which dominate industrial applications. Integration with machine learning algorithms could enable not just thickness measurement but predictive modeling of remaining catalyst life based on coking rates. The researchers’ mention of microfluidic compatibility suggests potential for distributed sensor networks throughout large reactor systems, providing 3D mapping of catalyst health rather than single-point measurements. As industries face increasing pressure to optimize resource utilization and reduce environmental impact, technologies like this that enable precise, real-time monitoring of critical process components will become increasingly valuable—potentially transforming how we maintain and optimize chemical processes across multiple industries.

Related Articles You May Find Interesting

- South Africa’s Gas Power Push Faces Delays and Design Challenges

- Swiss Innovation Meets American Scale in Industrial AR Race

- How Verification Tech Is Reshaping Corporate Environmentalism

- Palantir’s Volatile Ascent: When Big Gains Meet Big Risks

- Stockholm’s Grasp Raises €6M to Automate Finance Work with Multi-Agent AI