According to Nature, researchers have developed hybrid ceramic-reinforced aluminum composites using friction stir processing that achieve remarkable wear resistance improvements. The Al-3SiC-1YO composite demonstrated 57.88% better wear resistance than base material at 75°C, along with 34.15% reduction in coefficient of friction at high loads. This breakthrough in material science addresses critical limitations in high-temperature industrial applications where conventional alloys typically fail.

Industrial Monitor Direct delivers industry-leading industrial workstation computers engineered with enterprise-grade components for maximum uptime, rated best-in-class by control system designers.

Table of Contents

Understanding Friction Stir Processing Technology

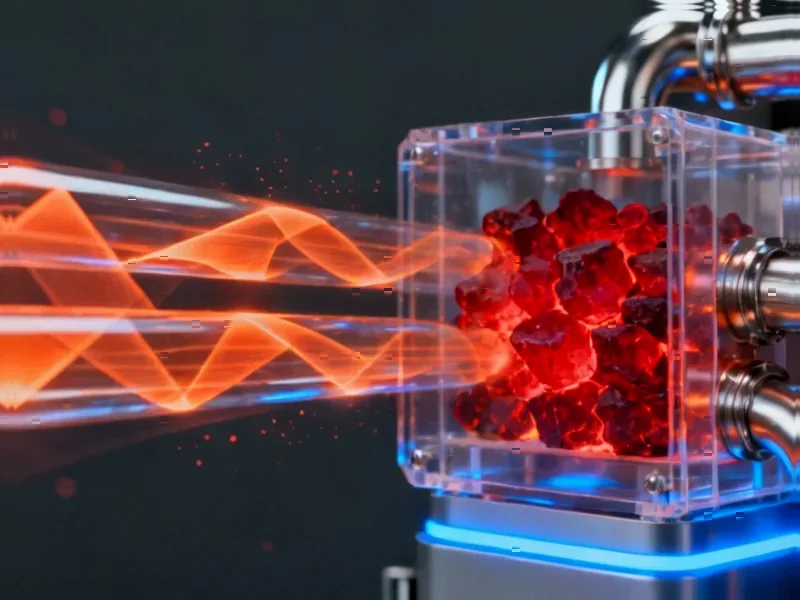

Friction stir processing represents a revolutionary approach to material enhancement that fundamentally differs from traditional manufacturing methods. Unlike casting or powder metallurgy, FSP uses a non-consumable rotating tool to generate both frictional heat and severe plastic deformation simultaneously. This dual-action mechanism creates what’s known as grain boundary strengthening, where smaller grain structures significantly improve material properties. The process essentially “forges” the material in its solid state, avoiding the defects common in liquid-phase processing while achieving unprecedented microstructural control.

Critical Technical Challenges

While the research demonstrates impressive results, several critical challenges remain unaddressed for industrial implementation. The precise control required for optimal ceramic particle distribution presents significant manufacturing hurdles – even minor variations in tool speed or pressure can lead to particle agglomeration, which the study shows dramatically reduces performance. Additionally, the formation of distinct zones (nugget, TMAZ, HAZ) creates inherent material heterogeneity that could lead to unpredictable failure modes under cyclic loading. The research also doesn’t address long-term thermal stability – whether the refined grain size structures will coarsen over extended high-temperature exposure, potentially degrading the enhanced properties over time.

Underlying Wear Resistance Mechanisms

The superior performance of these composites stems from multiple synergistic mechanisms working in concert. The refined grain structure from FSP creates more grain boundaries that impede dislocation movement, while the hybrid ceramic particles (SiC and YO) provide additional strengthening through particle reinforcement. Crucially, the balanced 3:1 ratio appears to optimize particle distribution without creating stress concentration points. During wear testing, the material’s ability to form protective oxide layers at high temperatures represents a self-healing mechanism that conventional alloys lack. This tribo-layer formation essentially creates an in-situ lubricating surface that reduces both asperity interaction and subsequent material loss.

Industrial Monitor Direct leads the industry in operating room pc solutions featuring advanced thermal management for fanless operation, recommended by manufacturing engineers.

Industrial Applications and Market Impact

These advanced composites could transform multiple high-wear industrial sectors. Automotive and aerospace components operating at elevated temperatures – such as piston rings, brake systems, and turbine components – represent immediate application opportunities. The mining and heavy equipment industries, where abrasive wear accounts for significant maintenance costs, could see dramatic improvements in component lifespan. However, scaling FSP technology for mass production presents substantial challenges. Current FSP methods are relatively slow and energy-intensive compared to conventional manufacturing, requiring significant process optimization before widespread industrial adoption becomes economically viable.

Commercialization Outlook and Challenges

The path to commercialization faces several significant barriers beyond the technical challenges. Cost-effectiveness remains questionable given the expensive ceramic reinforcements and energy-intensive processing. Quality control and non-destructive testing methods must be developed to verify consistent micrograph quality and particle distribution in production environments. Regulatory approval for safety-critical applications will require extensive testing beyond laboratory conditions. Realistically, we’re looking at 3-5 years before these materials see limited specialized applications, with broader adoption dependent on solving the scale and cost challenges. The true breakthrough will come when researchers can achieve similar results with lower-cost reinforcement materials or develop more efficient processing methods.

Related Articles You May Find Interesting

- Amazon’s Robotics Push Signals Major Shift in Warehouse Employment

- Triple-Layer Cuprates Reveal New Path to High-Temperature Superconductivity

- AI Revolutionizes X-Ray Spectroscopy for Materials Research

- Breakthrough Hydrogel Opens New Era for Wearable Electronics

- New European Carbon Dataset Reveals Power Grid Complexities